Die Cutting Explained

You may well encounter various products that can be die-cut to a custom shape. But what does that mean? And more importantly, how can it help you create the perfect printed product? Read on to learn all about die cutting…

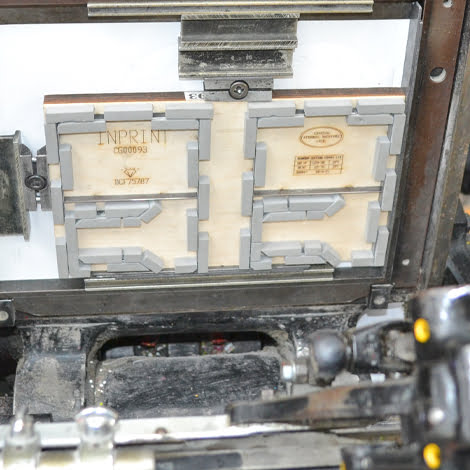

What is Die Cutting

In the world of printing, die cutting is a useful technique for creating custom shapes quickly and affordably. It involves printing your design onto a rectangular or square sheet of material, such as paper or card, and then using a specially made die or punch block to cut the material into the desired shape. The die is typically made of wood and features a metal blade that has been bent and folded to create the desired shape. When the printed sheet and the die are pressed together in a machine, the blade cuts out the shape from the material in a single pass, making it a fast and efficient way to produce shaped items like Table Talkers.

Die cutting is for more than just eye catching custom shaped flyers however, it also helps create the more functional aspects of printed products such as pockets and flaps on folders and boxes plus the curves, circles and intricate interlocking elements on our speciality print.

Die cut block

Block mounted on platten

Custom cut boxes

Why is die-cutting beneficial?

Die-cutting is a time-efficient method that can help you create custom-shaped products effortlessly. Unlike digital cutting that takes longer to navigate through curves and corners, die-cutting allows you to cut your desired shape in one go. After creating your die or punch block, you can repeatedly use it to cut hundreds of identical, custom-shaped products. This is especially useful when creating products such as Table Talkers that require a uniform shape.

Which materials can be die-cut?

Die-cutting involves using a sharp metal tool called a die to cut a specific shape out of a material, such as paper or card. Because the cutting action of a die involves punching through the material, it works best on low strength materials such as paper and card, which are relatively easy to cut through.

What about foamboard, correx and dibond?

When it comes to creating Table Talkers using heavier weight large format materials, a digital die-cutting process may be necessary. Unlike traditional die cutting, which relies on physical dies to create the shape, digital cutting employs a blade that follows a computer-programmed path to create the desired design.

The equipment used for digital cutting typically includes a flat table area and a set of cutting, milling, and scoring attachments mounted on an arm. This arm enables the cutter to move in any direction, including left, right, forwards, and backwards, allowing for precise and complex cuts.

To create Table Talkers, the printed sheet is placed on the table, and the cutter then moves across the sheet along the programmed path, cutting out the desired shape with accuracy and speed. With digital die-cutting, it’s possible to work with heavier weight materials and achieve a high degree of precision and consistency in the finished product.

Digital die cut paper and card

Thanks to advancements in technology, it’s now possible to produce “die-free” cutting with excellent results on a whole range of paper and card weights. One of the main benefits of this cutting method is that it bypasses the need for an expensive die block, which can help to keep both production times and costs down.

While digital die cutting may not be able to match the output volume of traditional die cutting, it’s a perfect option for lower print runs or when creating prototypes for larger die cutting formes. With digital die cutting, you can achieve a high degree of precision and consistency, making it an excellent choice for creating intricate designs.

Overall, the ability to use die-free cutting methods provides greater flexibility and efficiency when producing Table Talkers or other printed materials, as it allows for quicker turnaround times and more cost-effective production.

Digitally cut cake box

If you have any more questions about die cutting, traditional or digital call us on 023 8087 8037 or email us.